Revolutionizing Business with Advanced 3D Printing Technologies and Street Sweeper Equipment

In today's rapidly evolving industrial landscape, innovation is the cornerstone of competitive advantage. Businesses that leverage emerging technologies like 3D printing are positioned to accelerate product development, reduce costs, and enhance customization. Among the many sectors embracing this revolution, manufacturing of street sweeper equipment stands out as a prominent example of how 3D printing is transforming traditional manufacturing paradigms.

Understanding the Power of 3D Printing in Modern Business

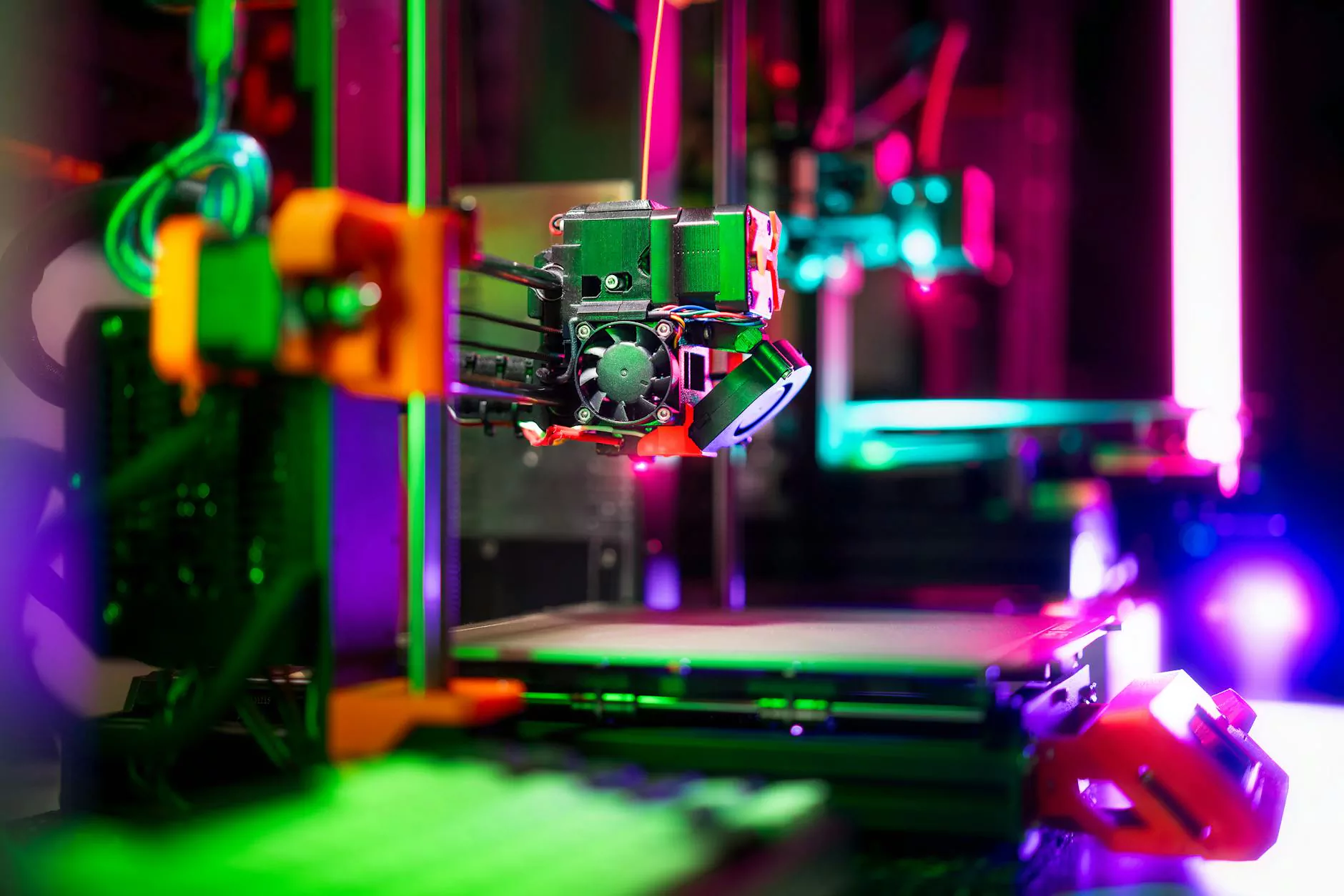

3D printing, also known as additive manufacturing, involves creating three-dimensional objects by layering materials based on computer-aided design (CAD) models. This technology offers remarkable flexibility, precision, and speed, allowing businesses to innovate faster and more efficiently than ever before.

The Business Benefits of 3D Printing

- Rapid Prototyping: Reduce product development cycles by quickly creating prototypes for testing and validation.

- Cost Efficiency: Lower manufacturing costs, especially for small batch productions or custom parts, by minimizing material waste and reducing tooling expenses.

- Design Flexibility: Explore complex geometries and innovative designs that are difficult or impossible to produce with traditional manufacturing methods.

- Supply Chain Optimization: Facilitate localized production, reducing reliance on extensive supply chains and logistics.

- Sustainability: Use environmentally friendly materials and produce less waste, aligning with green manufacturing initiatives.

How 3D Printing Enhances Manufacturing of Street Sweeper Equipment

At ceksansweepers.com, leading innovations include integrating 3D printing into the design and production of street sweeper equipment. This integration unlocks numerous advantages for both manufacturers and clients, ensuring high-quality, durable, and customized solutions.

Design Optimization and Rapid Prototyping for Street Sweeper Parts

By utilizing 3D printing, engineers can quickly develop prototypes of components like sweeper brushes, nozzles, or hopper parts. This rapid iteration process enables thorough testing and refinement, drastically reducing the time from conception to production. The ability to test complex geometries—such as optimized airflow paths or ergonomic interfaces—enhances the overall efficiency and effectiveness of street sweeping systems.

Customization Tailored to Specific Needs

Each urban environment presents unique challenges, requiring tailored street sweeper equipment. 3D printing allows for rapid customization of parts, ensuring that each piece of equipment is optimized for particular street conditions, traffic patterns, and cleaning requirements. This customization improves cleaning performance, extends equipment life, and enhances customer satisfaction.

Cost Reduction and Material Innovation

Traditional manufacturing of heavy-duty components can be costly and time-consuming. 3D printing minimizes these barriers by enabling on-demand production of parts, significantly reducing inventory costs and lead times. Furthermore, advancements in printable materials—including high-strength polymers and composites—provide durable, wear-resistant components suitable for demanding street sweeping applications.

Comprehensive Advantages of Adopting 3D Printing in Street Sweeper Manufacturing

Implementing 3D printing technologies into the production cycle offers several strategic advantages:

- Accelerated Innovation: Quickly test new designs, leading to continuous improvements in equipment performance.

- Reduced Downtime: Produce replacement parts on-site or locally, minimizing machine downtime and improving operational efficiency.

- Enhanced Product Lifecycle Management: Keep spare parts inventory minimal while ensuring rapid availability for maintenance and repairs.

- Increased Sustainability: Use eco-friendly 3D printing materials, waste reduction, and localized manufacturing contribute to greener operations.

- Competitive Differentiation: Offer clients bespoke solutions that match their specific needs, backed by innovative manufacturing methods.

The Future of Business in 3D Printing and Street Sweeper Equipment

The continual evolution of 3D printing technology is set to redefine how companies approach manufacturing, especially in sectors requiring precision, durability, and customization such as street sweeping. The integration of emerging printing techniques—like multi-material printing, metal additive manufacturing, and large-format printing—will further expand capabilities, delivering even more sophisticated and efficient street sweeper solutions.

Moreover, as digital workflows become more integrated with 3D printing, businesses will benefit from enhanced automation, better supply chain visibility, and data-driven design optimization. This will result in faster response times to market demands, increased product diversity, and sustainable growth.

Why Choose Ceksansweepers.com for Your Street Sweeper Equipment Needs

- Expertise in 3D Printing Integration: Leading the industry in incorporating 3D printing for innovative manufacturing processes.

- High-Quality Manufacturing: Providing durable, reliable, and custom-made street sweeper equipment suited for various urban and industrial applications.

- Custom Solutions: Offering tailored designs to meet specific client needs, leveraging the flexibility of 3D printing.

- Global Reach and Local Service: Combining advanced manufacturing with excellent customer support to serve clients worldwide.

- Commitment to Sustainability: Embracing eco-friendly practices through innovative material use and manufacturing techniques.

Join the Future of Business Innovation with Ceksansweepers.com

As the industry takes strides toward more sustainable, efficient, and customized manufacturing, Ceksansweepers.com stands at the forefront with pioneering solutions in 3D printing and street sweeper equipment. Investing in these advanced manufacturing techniques ensures your business stays ahead of the curve, delivering superior products that meet the evolving demands of urban cleaning and environmental responsibility.

Final Thoughts: Embracing Innovation to Drive Business Success

In conclusion, leveraging 3D printing technology in the manufacturing of street sweeper equipment offers unmatched opportunities for innovation, efficiency, and customer satisfaction. As industries continue to modernize and prioritize sustainability, integrating these cutting-edge techniques will become essential for businesses aiming to lead in today's competitive landscape. Choose Ceksansweepers.com as your trusted partner in pioneering the future, and witness your business experience transformation through technological excellence and strategic innovation.